Laser Cutting

For today the laser cutting is the most popular and widespread operation.

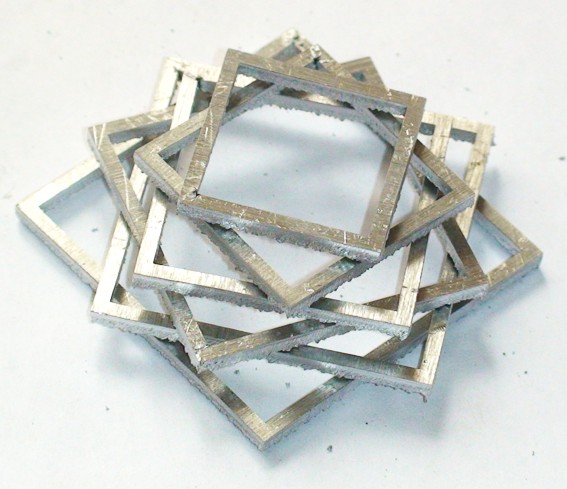

Thanks to possibility of operational control of laser beam parameters the vario-head VF enables optimization of cut quality for different materials and metal thicknesses. At the same time the operations are executed rapidly and with the highest accuracy. Speed and efficiency of fibre laser cutting are 1.5–4 times higher than the classical cutting (depending on material); cut width is 1.5–2 times less and can reach 0.1 mm.

Work with different metal thicknesses allows sketching, cutting and marking different prefabricated parts with minimum time loss and minimum deformation of source material and final structure.

Furthermore, the high accuracy of cutting and vario-head capabilities make it possible to perform operation like manufacture of slotted filters in pipes for oil-producing industry: pipe thickness up to 9 mm and regulated geometry, thickness at the input 0.1.0.2 mm, at the output 0.4.0.7 mm. Cutting can be performed outside and inside the pipe.

Main parameters of cutting:

|

Regulated cutting width |

80 to 250 micron |

|

Regulated cutting width 80 to 250 micron Cutting width (max) at laser power of 1000 (2000) W:

-

carbon steels

-

stainless steels

-

aluminium alloys

-

copper

|

10 (18) mm

9 (16) mm

6 (12) mm

1.5 (4 mm)

|